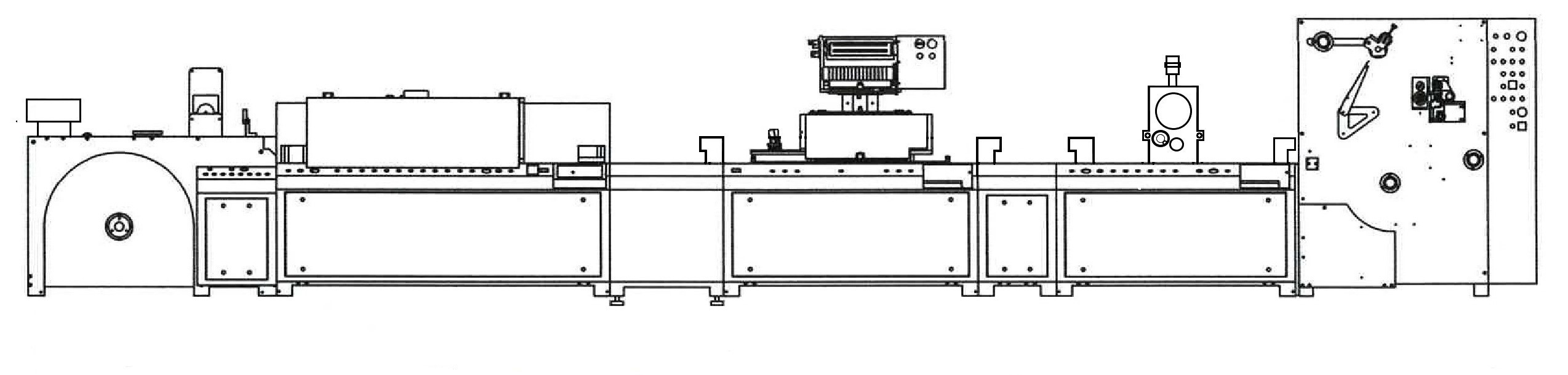

Model

BERRA MASTERPRINT 350

Printing and finishing machine for high-speed production and top-quality ennobling.

The semi-rotary screen printing units and the new rotary cast gold units allow this machine to achieve maximum details definition, with extremely fast start-up times and minimal waste of material.

Possibility of inserting multifunctional flexo printing units with 4 different applications:

Single-color printing, Continuous full-table varnishing, Partial drip-off varnishing in sectors and Adhesive and cold lamination with glue spreading via anilox roller and/or cold lamination.

The entire line is completely modular.

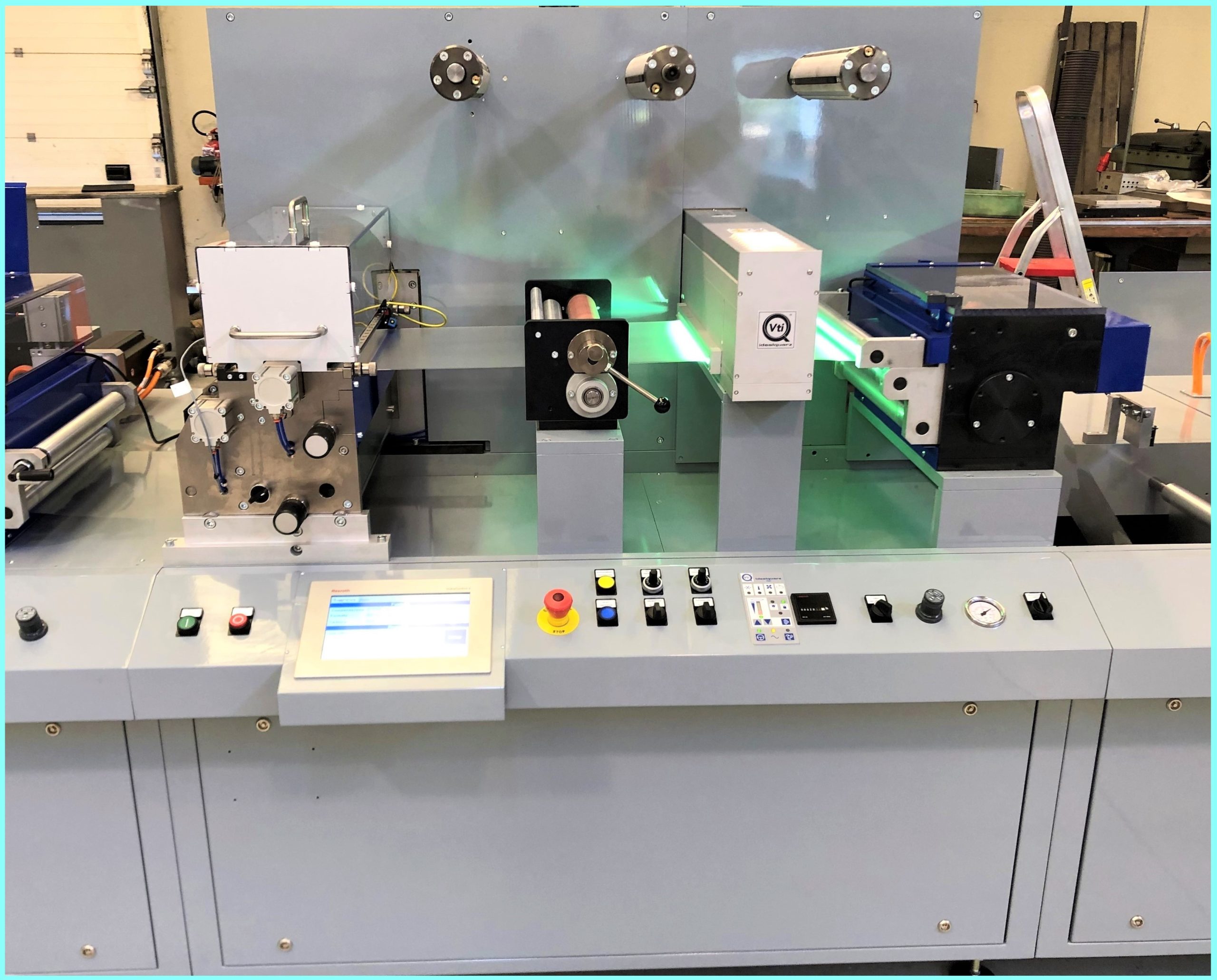

Each individual unit is equipped with its own new self-centering auto-register system, supplied with register gap recovery.

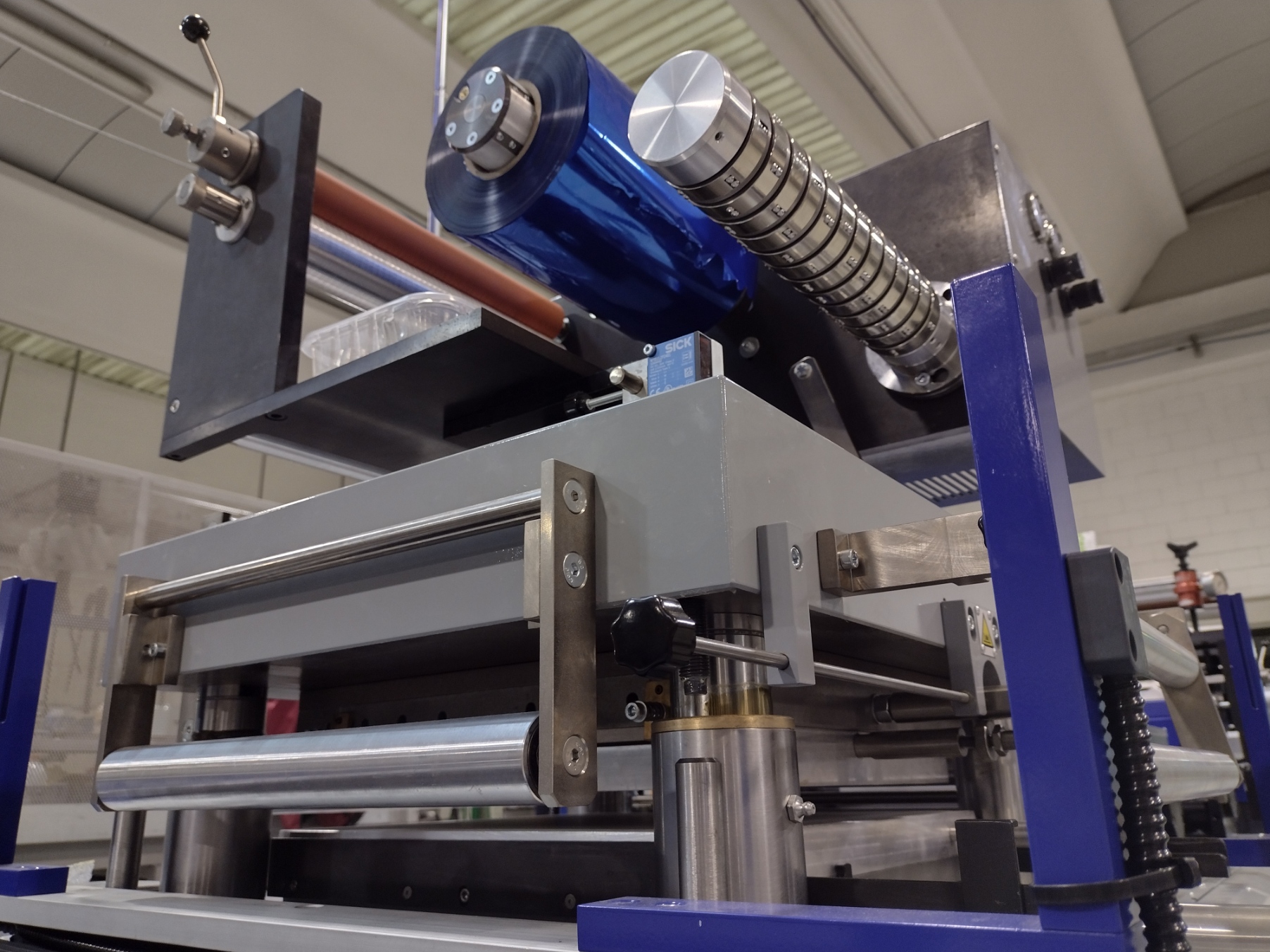

A choice of several different interchangeable hot stamping units is available, such as: Variable pitch with double foil on independent shafts; Multifoil with single 76 mm friction shaft capable of printing up to 4 foils with different colors and reel diameters simultaneously.

New Tor group with enhanced structure, improved tonnage pressure and heat resistance. The Foil Group unwinding and rewinding motors are controlled with dedicated drives, which allow to optimize the tension of the material, even at high speeds. The perfectly flat pressure is obtained by two opposing cones, and enabled by a servomotor.

Semi-rotary die-cutting unit with compensation in case of lamination deformation, Gap Master and new automatic and complete EasyLiner stripping/rewinding unit, to complete the entire coil-processing phase directly in the machine.

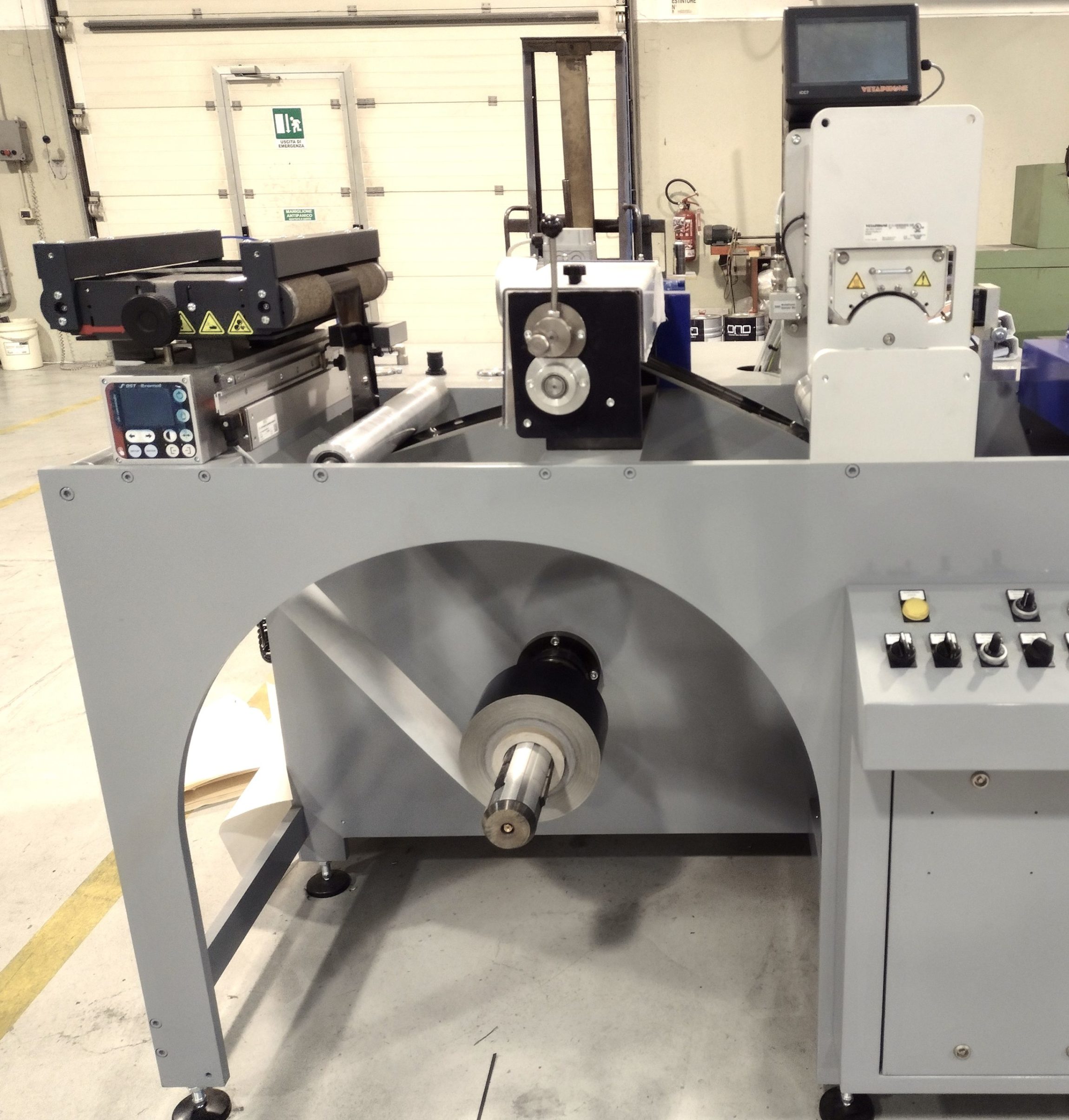

- Unwinder with BST WebGuide

- Corona Treatment VETAPHONE (Optional)

- Flexo UV and WATER BASED Printing and Varnishing Unit

– Adhesive and Cold Lamination System and Cold Foil (Optional) - Semi-Rotary Screen Printing Group (from 1 to max 6 MODULAR Units) with Self Automatic Centering System, named AUTOREGISTER

- Hot Foil Group with Self Automatic Centering System, named AUTOREGISTER MULTIFOIL (Optional TOR Version with strong structure, for hot foil and embossing with high definition). The whole Unit can rotate by 90° degrease.

- Adhesive Dry Lamination to remove the parts inside the Label

- LABEL OVERLAY SYSTEM ON LABEL IN REGISTER

- Flat Die Cutting Unit for embossing and debossing

- SEMI-ROTARY DIE CUTTING with GAP MASTER and sheet distorsion compensation

- Unwinding/Rewinding (New 2020) EASYLINER with Hot Plate

| Max diameter of reels on the unwinder |

mm 800 |

Max diameter of rewound spools |

mm 600 |

| Material feeding gap |

mm 350 |

Length of single modules |

mm 1.500/2.000 |

| Printing size |

340mm x 340mm |

Machine depth |

mm 1.500 |

| Remote Service |

Standard |

Flat Screen Printing Unit speed |

Up 25 mt/min 5.000/6.000 cicli/ora |

| Hot Foil Printing Unit speed |

Up to 40 mt/min 8.000 cicli/ora |

Flexo Unit and Semi-Rotary Die Cuttin Unit speed |

Up to mt/min 10.000 cicli/ora |