Model

INSPECTION SLITTER REWINDERS MACHINE 350

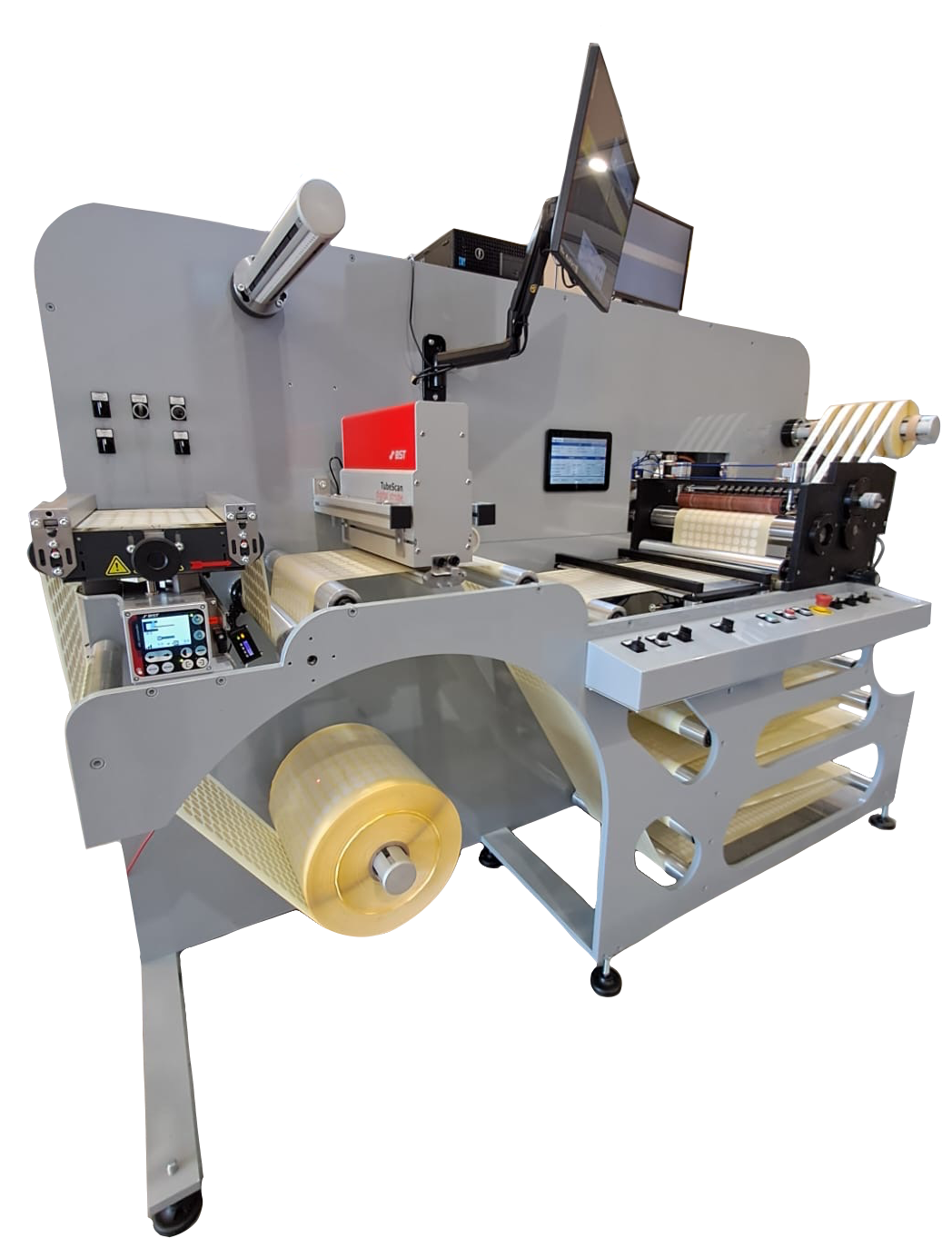

A machine conceived for the inspection and slitting of labels and other materials, easy to use and accessible, designed to favor ergonomics for the benefit of the operator and capable of inspecting at high speeds with precise stop upon defects.

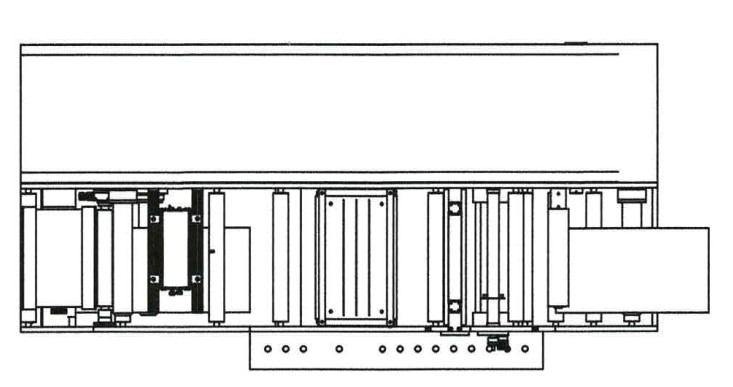

The machine is equipped with Bosch/rexroth electronics, servo motors and smart control drives from the latest generation allow the optimization of performance and guarantee the reduction of energy consumption.

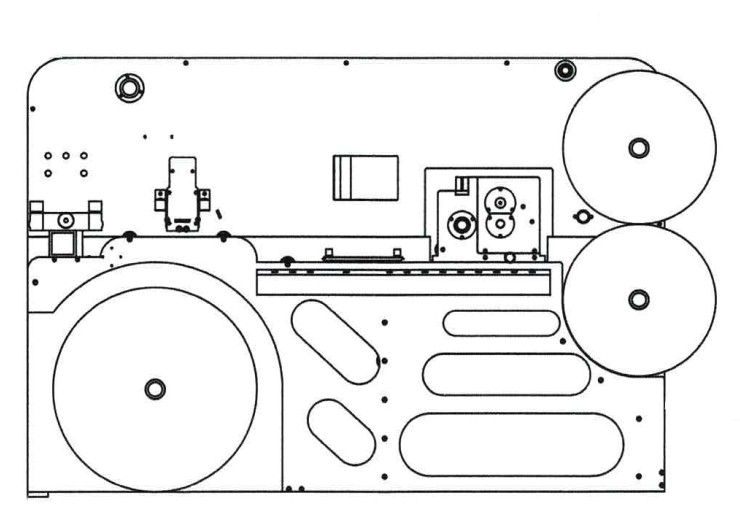

- Servo-motorized Unwinding Shaft with automatic control of the unwinding tension at the variation of the roll diameter

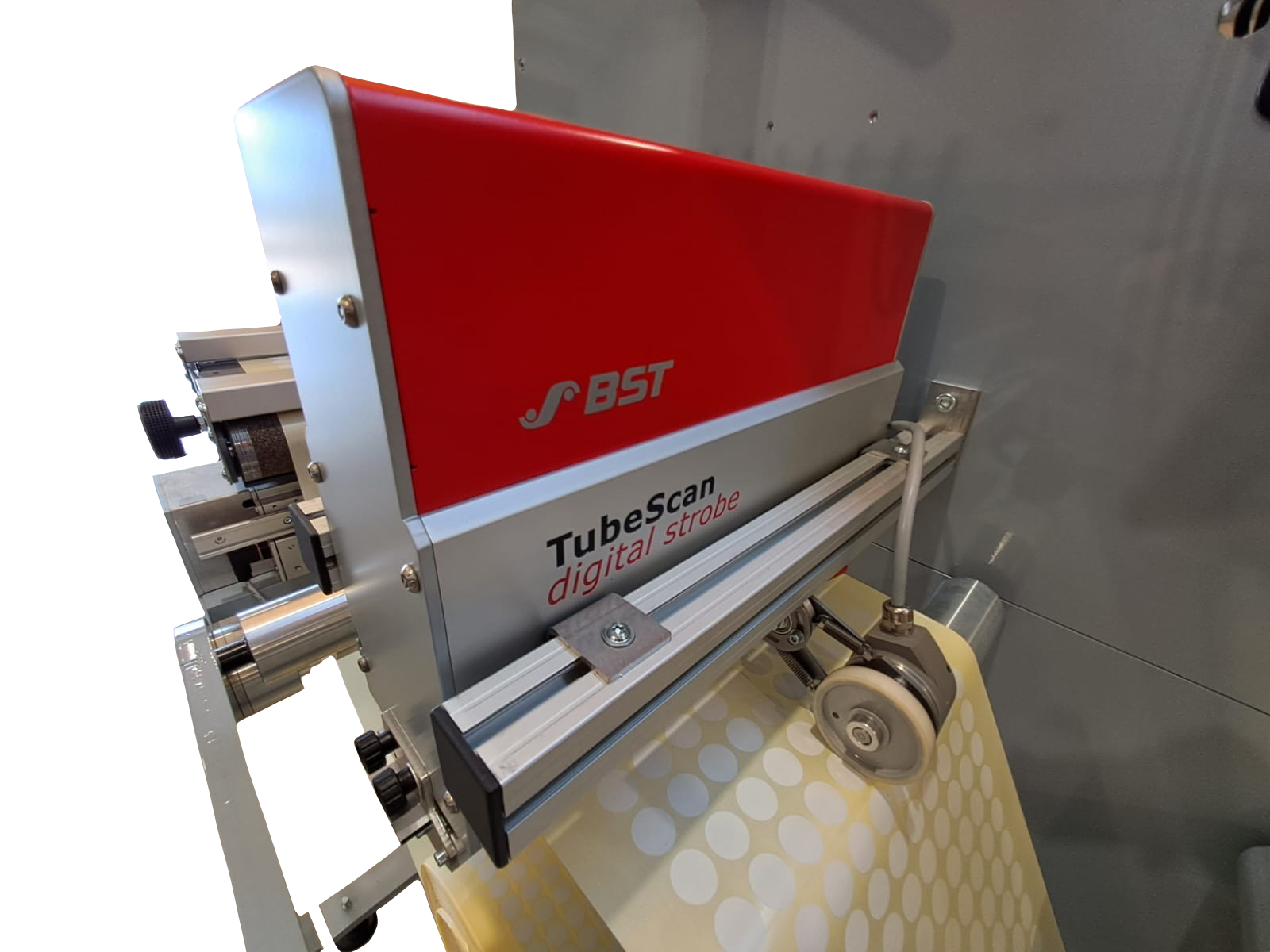

- BST Self Web Guiding System with ultrasonic sensor capable of managing even transparent materials

- Rewinding Shaft for waste printed material

- Splicing Table with pneumatic blocking of the material and adjustable position

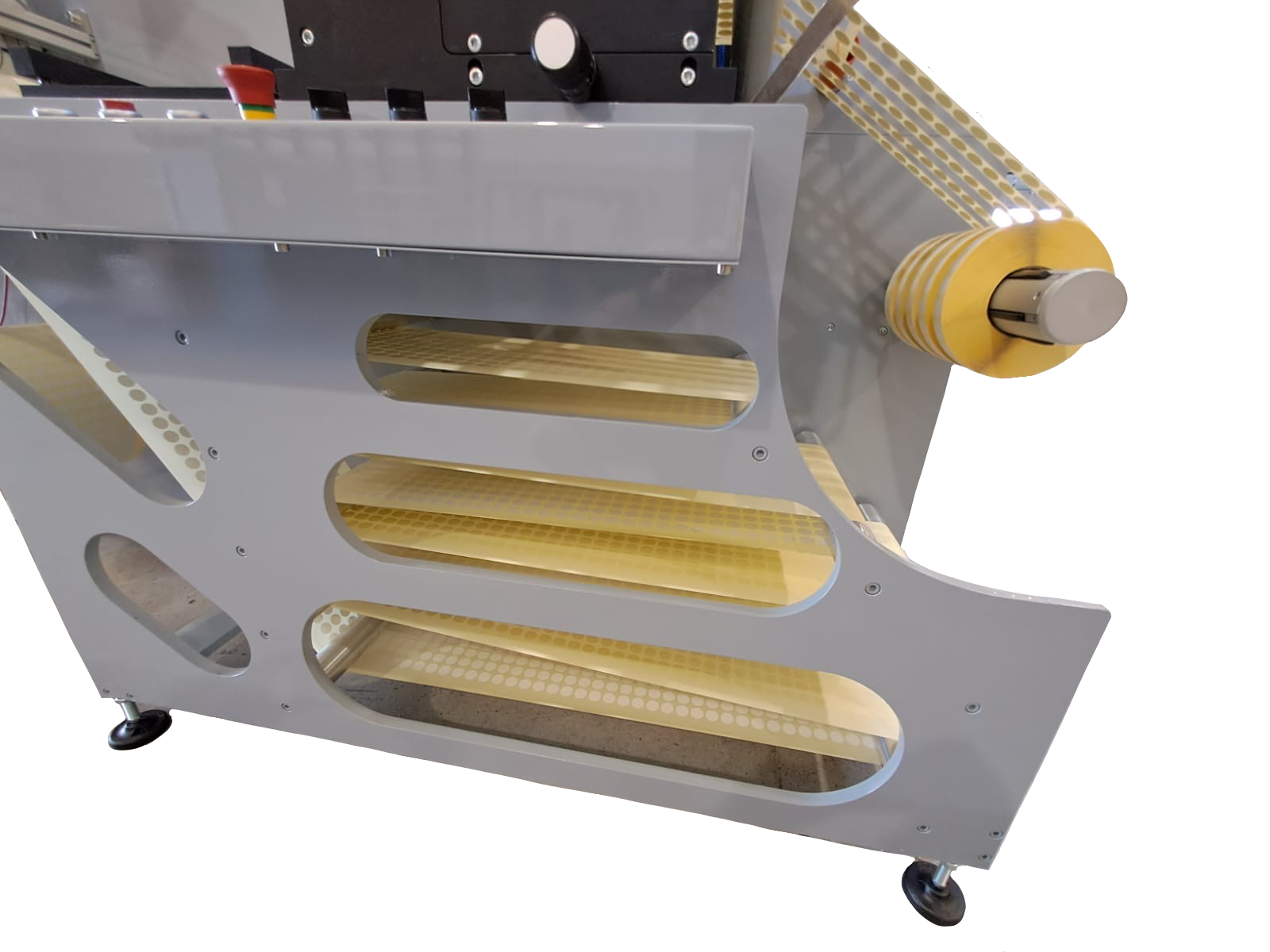

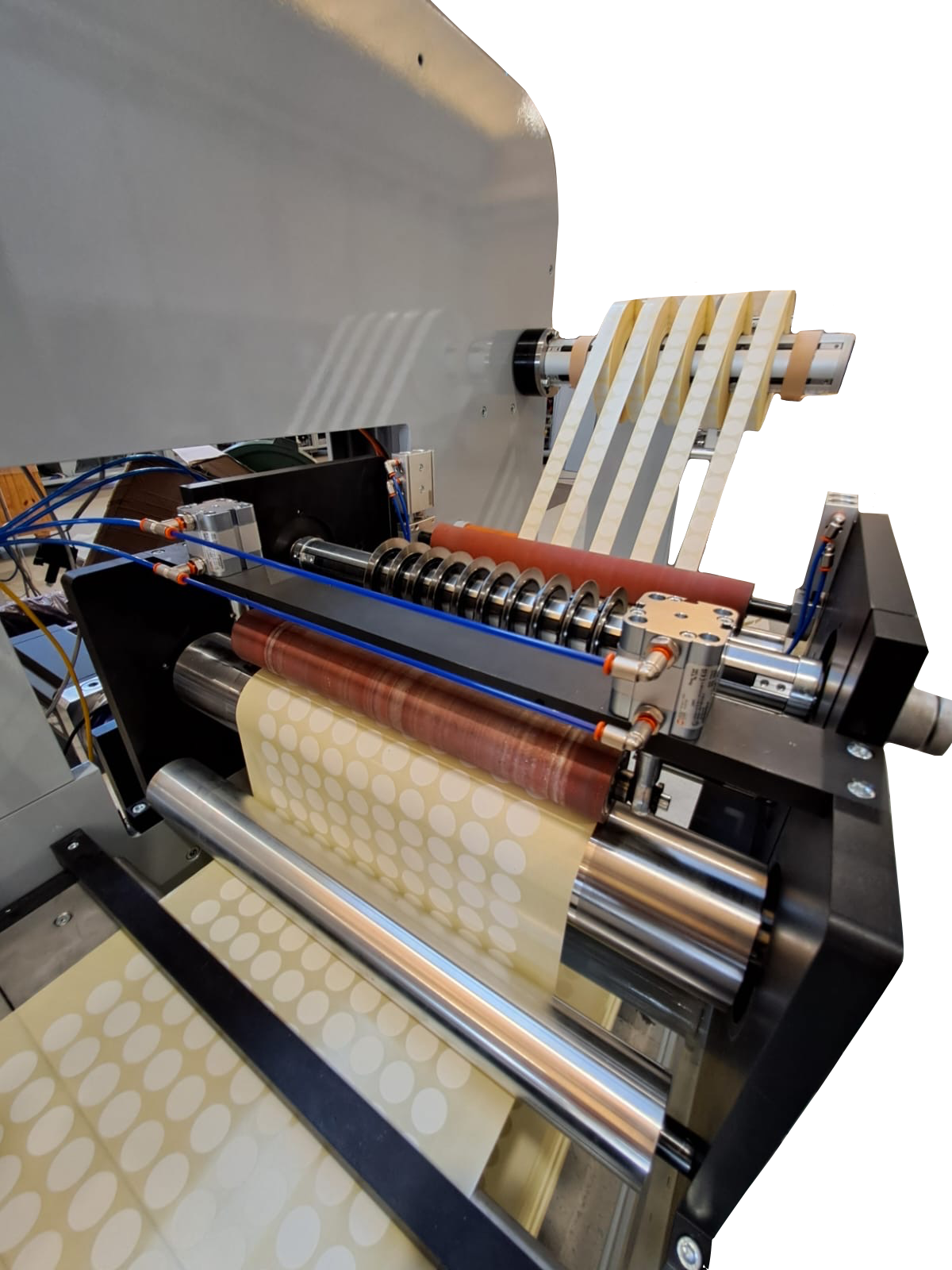

- Longitudinal Cutting Group with 6 circular blades

The movement of the blades and counterblades is manual with automatic blocking for quick preparation of the blades.

The entire unit can be moved laterally - Rewinding Shaft D.76 mm. servo-motorized with adjustable tension control.

Possibility to rewind the reels with labels inside or outside. - Ultrasonic photocell for label counting.

Possibility to count labels/meters/number of partial and total rolls. - Trimming aspirator for lateral waste

- Second Rewinding Shaft (optional)

- Tubescan camera for BST video inspection (optional)

| Max diameter of reels on the unwinder | mm 900 | Distance between blades | mm 15 |

| Max diameter of rewound spools (first shaft) | mm 600 | Material feeding gap | mm 350 |

| Max diameter of rewound spools (secons shaft) | mm 600 | Machine width | mm 1.280 |

| Rewinding shaft diameter | mm 76 | Inspection table speed | up to 300 Mts./min. |

| Velocità flexo e fustella semirotativa | fino a 10.000 cicli/ora |