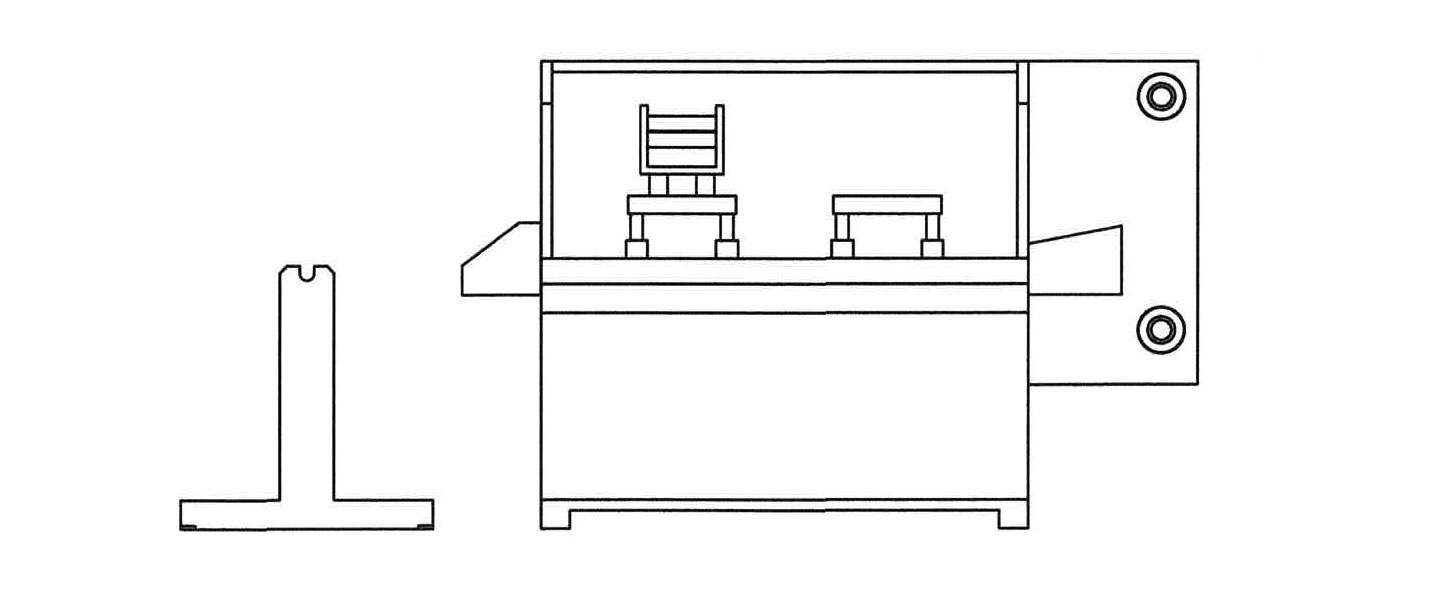

Model

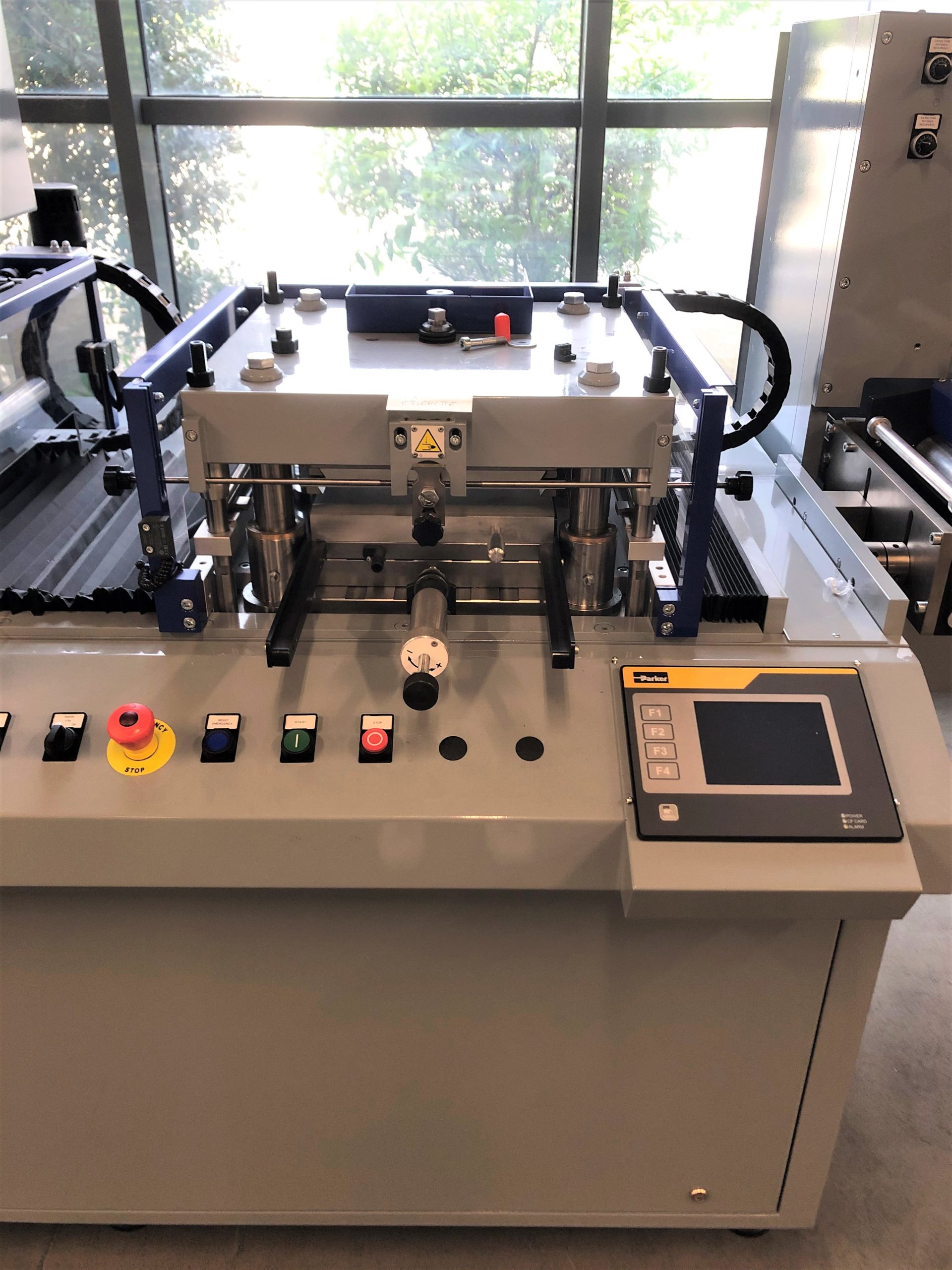

BERRA S2 250

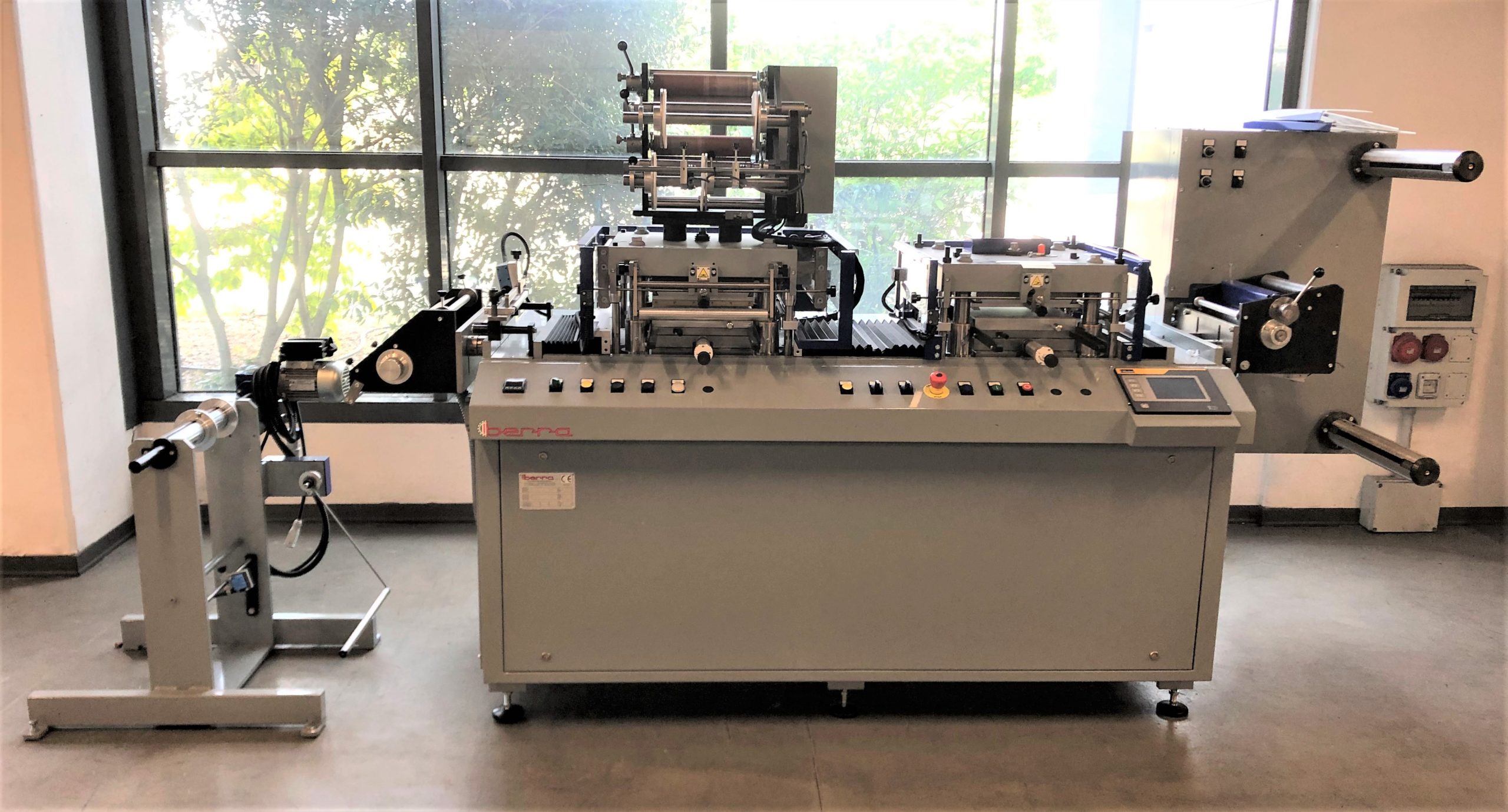

Modular reprocessing and finishing machine able to satisfy most needs by performing a wide range of processes.

Possibility to integrate silk-screen printing units of 310 mm width.

Characterized by a very sturdy structure, appreciated for its highly effective space-saving design, which makes it suitable for installation in limited spaces.

A convenient solution also in terms of price, as an entry level investment for startup companies that want to enter the market of roll-fed label finishing.

Ideal for large runs, it guarantees high production with maximum precision in hot stamping and flat die-cutting processes.

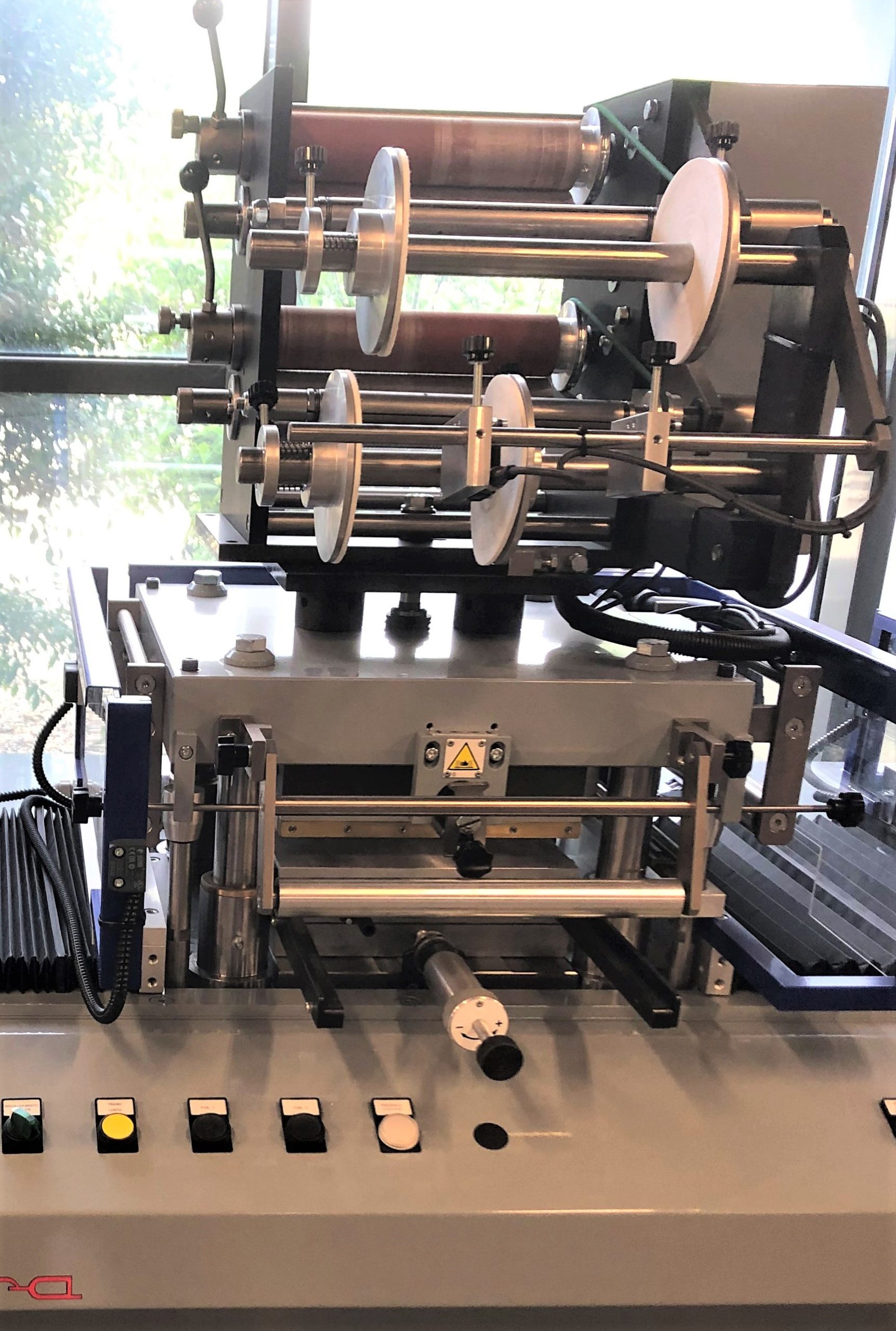

Vacuum brake on the suction side for good tensioning and control of the ribbon.

Thermal printing unit equipped with two servo-controlled shafts for variable pitch printing of 2 simultaneous foils. The unit can also perform a 90° rotation.

Flat die-cutting with embossing or debossing plate. Final rewinding plate with the possibility of adding a waste removal system with cutting blade technology.

- Unwinders:

– Manual version with 600mm diameter reel (standard)

– Automatic version with 800mm diameter reel (Optional) - Screen Printing Group with 330 light (Optional)

- Hot Printing Group with 2 lamination foils with rotation of the entire Group by 90°

- Flat die cutting/Embossing and debossing

- Rewinding Plate

- Razor cutting stripping system (Optional)

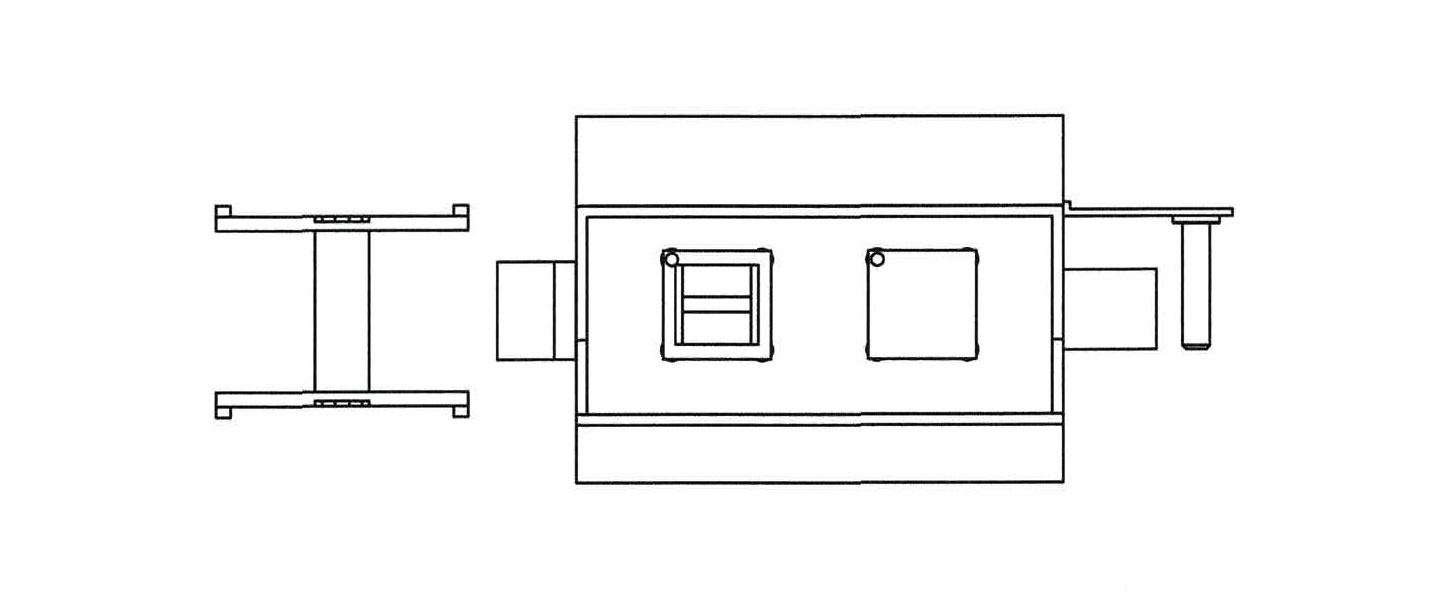

Model

BERRA S2 330

Modular reprocessing and finishing machine identical in every way to the S2 250 model, but with the possibility of integrating 330 mm wide silk-screen printing units.

| Max. diameter spools on the unwinder | mm 800 | Max. diameter rewound spools | mm 600 |

| Material feeding gap | mm 250 (mm 330 on model 330) | Length of single modules | mm 3.200 (mm 3.800 on model 330) |

| Printing size | mm 230 x 230 (mm 310 x 280 on model 330) | Machine depth | mm 1.500 |

| INDUSTRY 4.0 CONNECTIVITY | Optional | Flat Screen printing unit speed | up to 5.000 cycli/hour (330 mm adjustable printing width on request) |

| Thermal printing unit speed | up to 5.000 cycles/hour | Flexo unit and semi-rotary die-cutting speed | up to 5.000 cycles/hour |