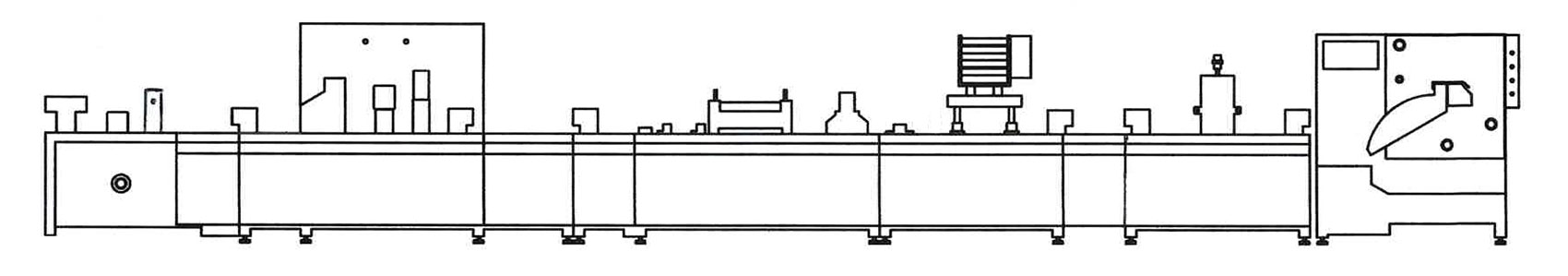

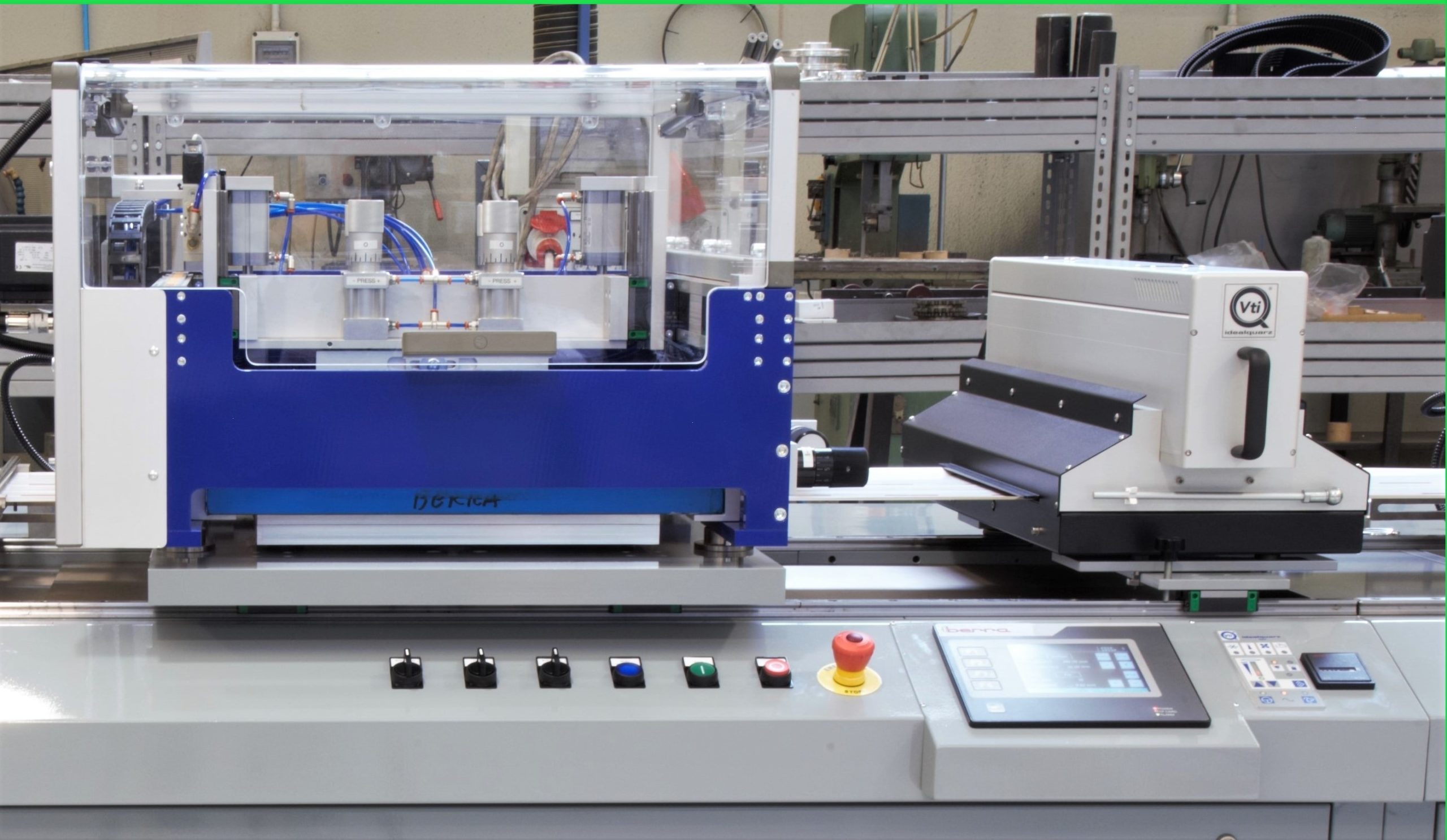

Model

BERRA HQS EVO 330

Modular label recovery and finishing machine.

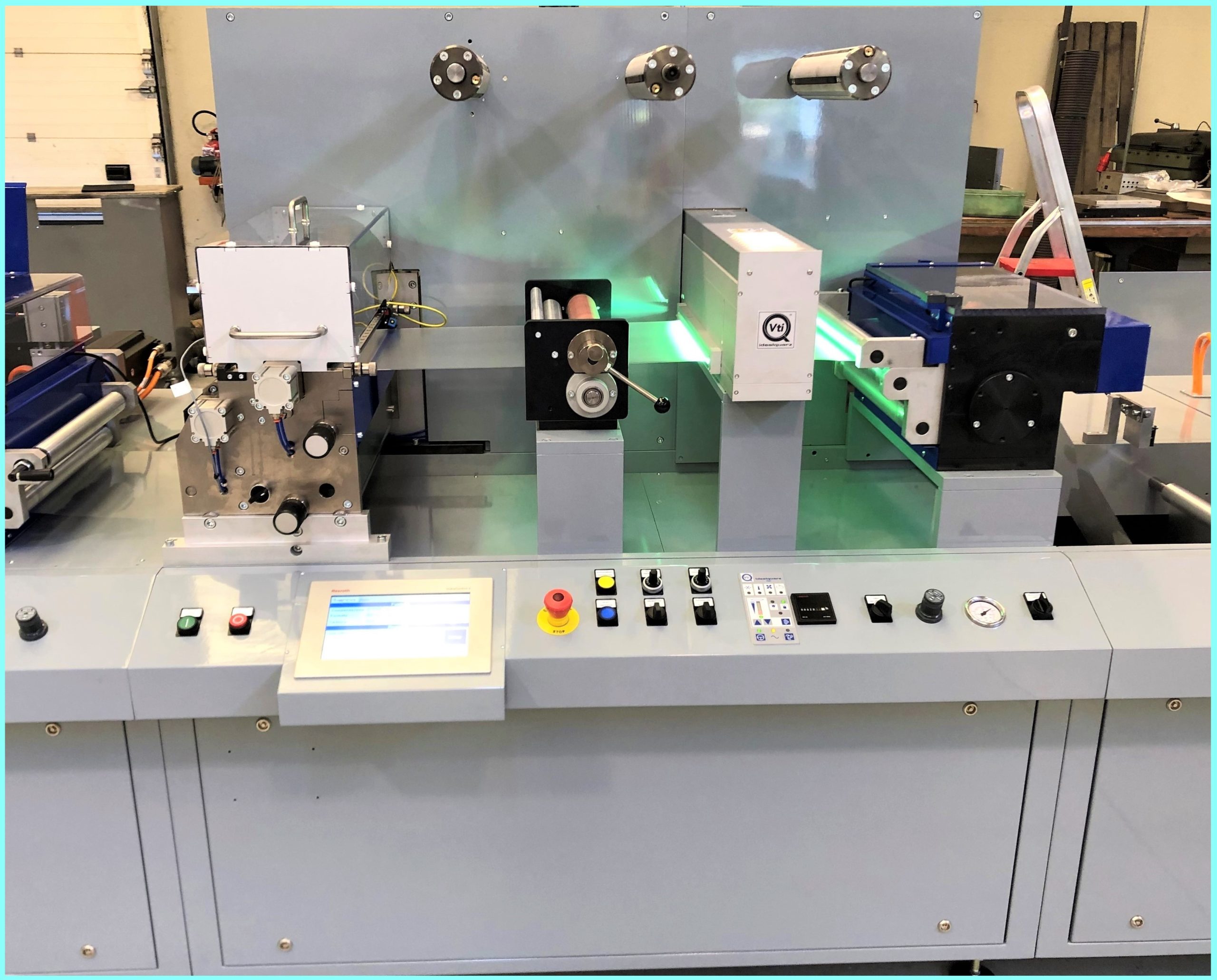

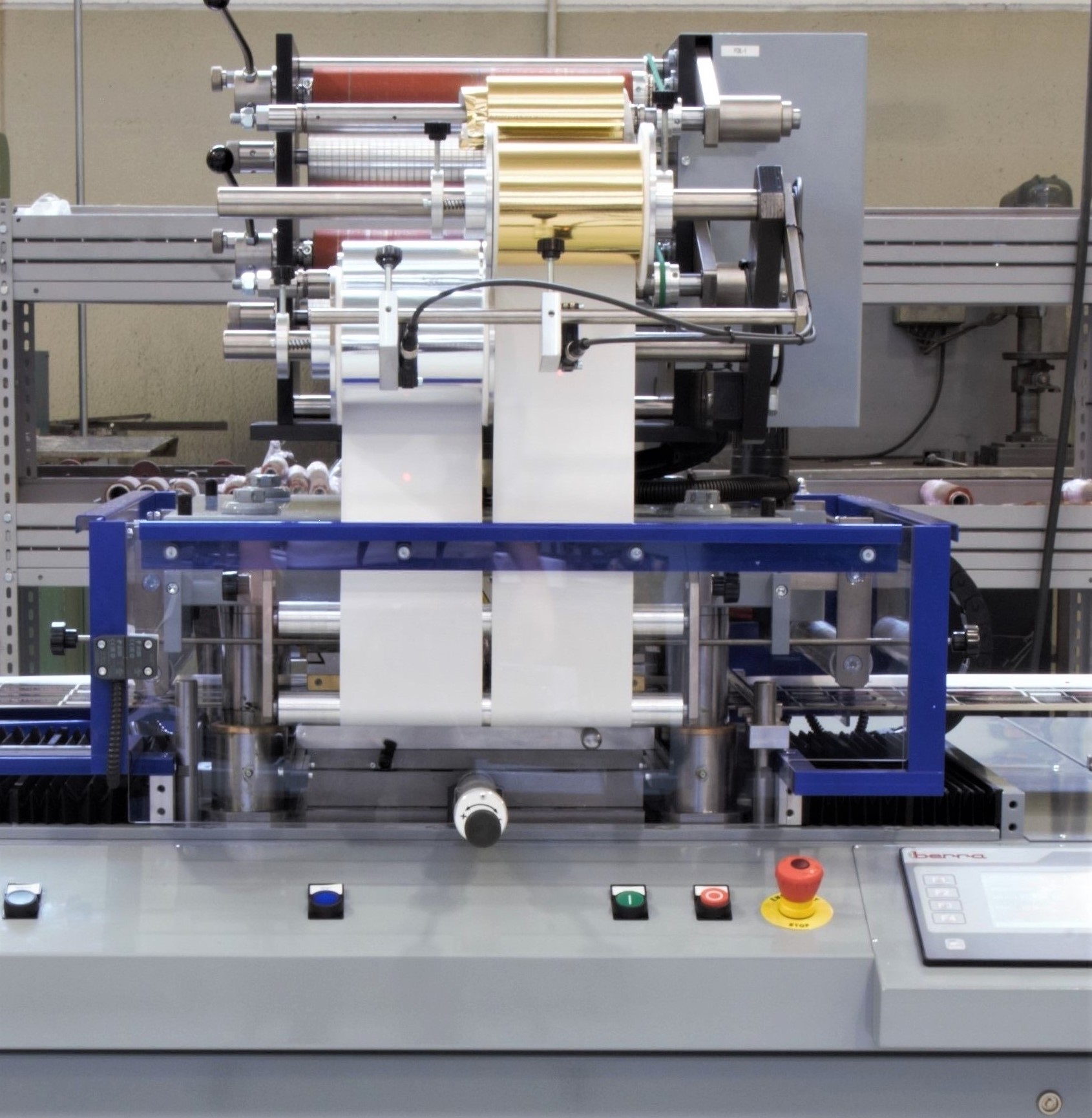

Bst band guide unwinder with automatic material self-centering system. Equipped with a multifunctional Flexo printing unit for 4 different applications: single-color printing; continuous varnishing over the entire surface; partial drip-off varnishing of individual areas and glue spreading via anilox roller for lamination and/or cold foil lamination.

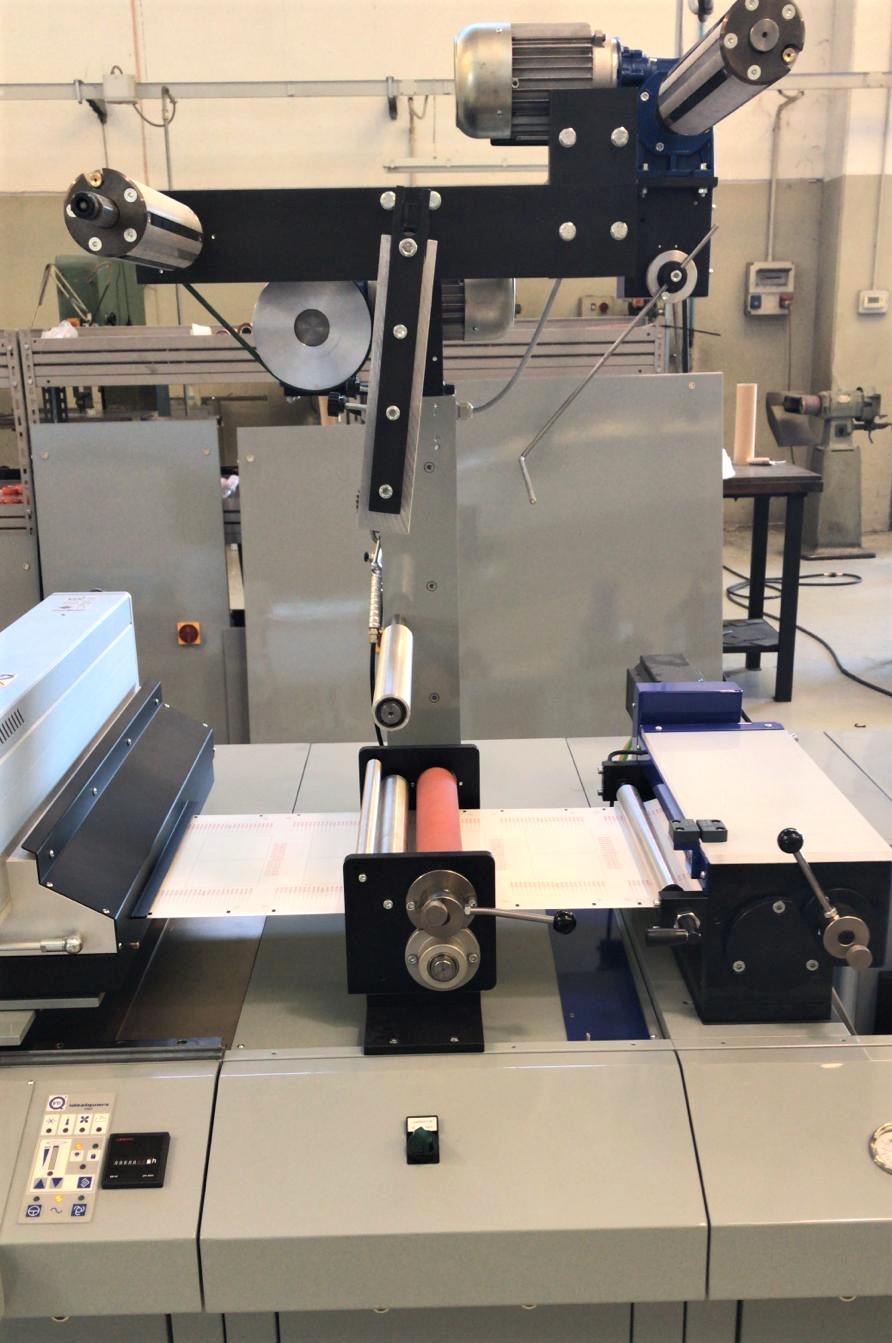

Capble of supporting up to 6 modular silk-screen printing units that can be equipped with “Autoregister new 2025″ with latest-generation Bosch/Rexroth management software.

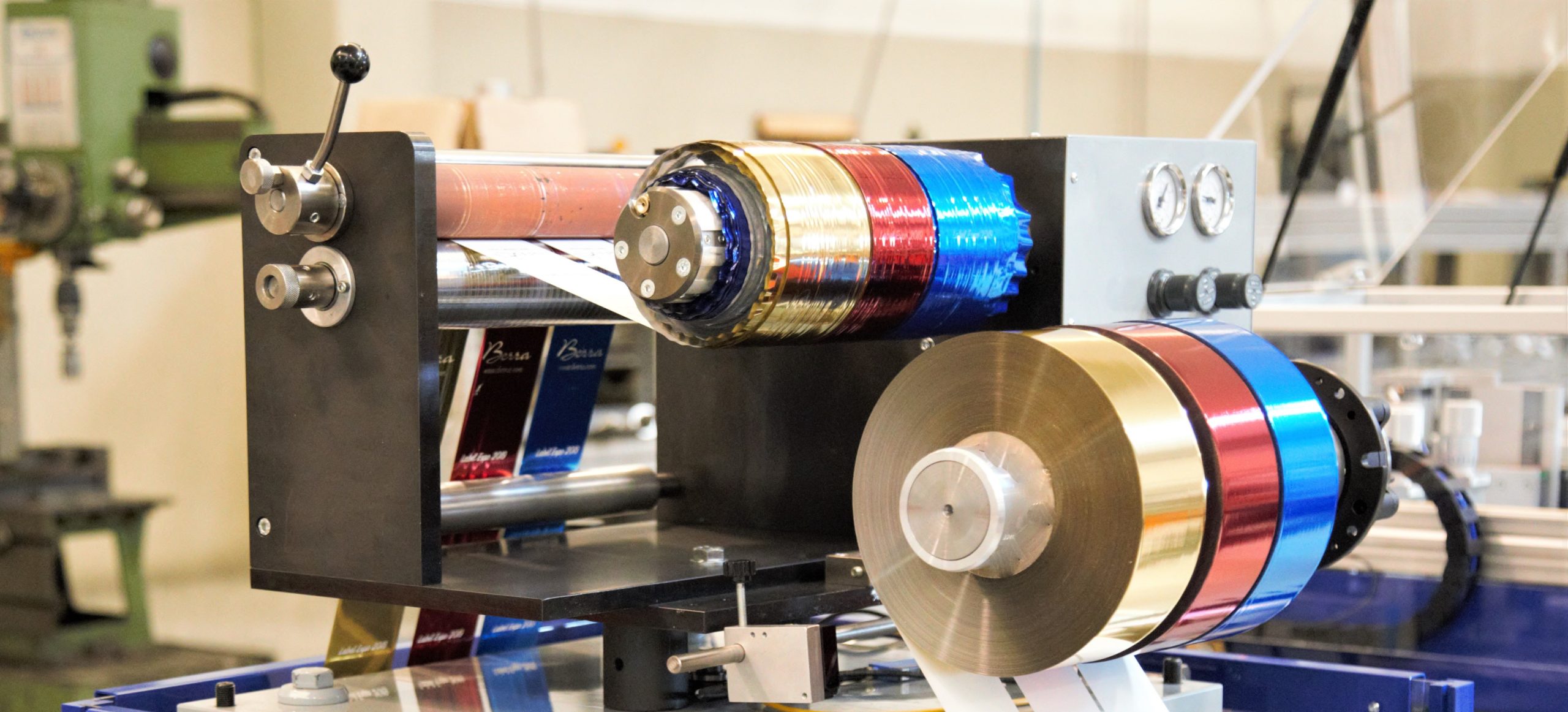

Modular hot stamping unit “Autoregister new 2025″ with latest-generation Bosch/Rexroth management software. Flat and semi-rotary version with Gap master.

Brushless motors on the entire line.

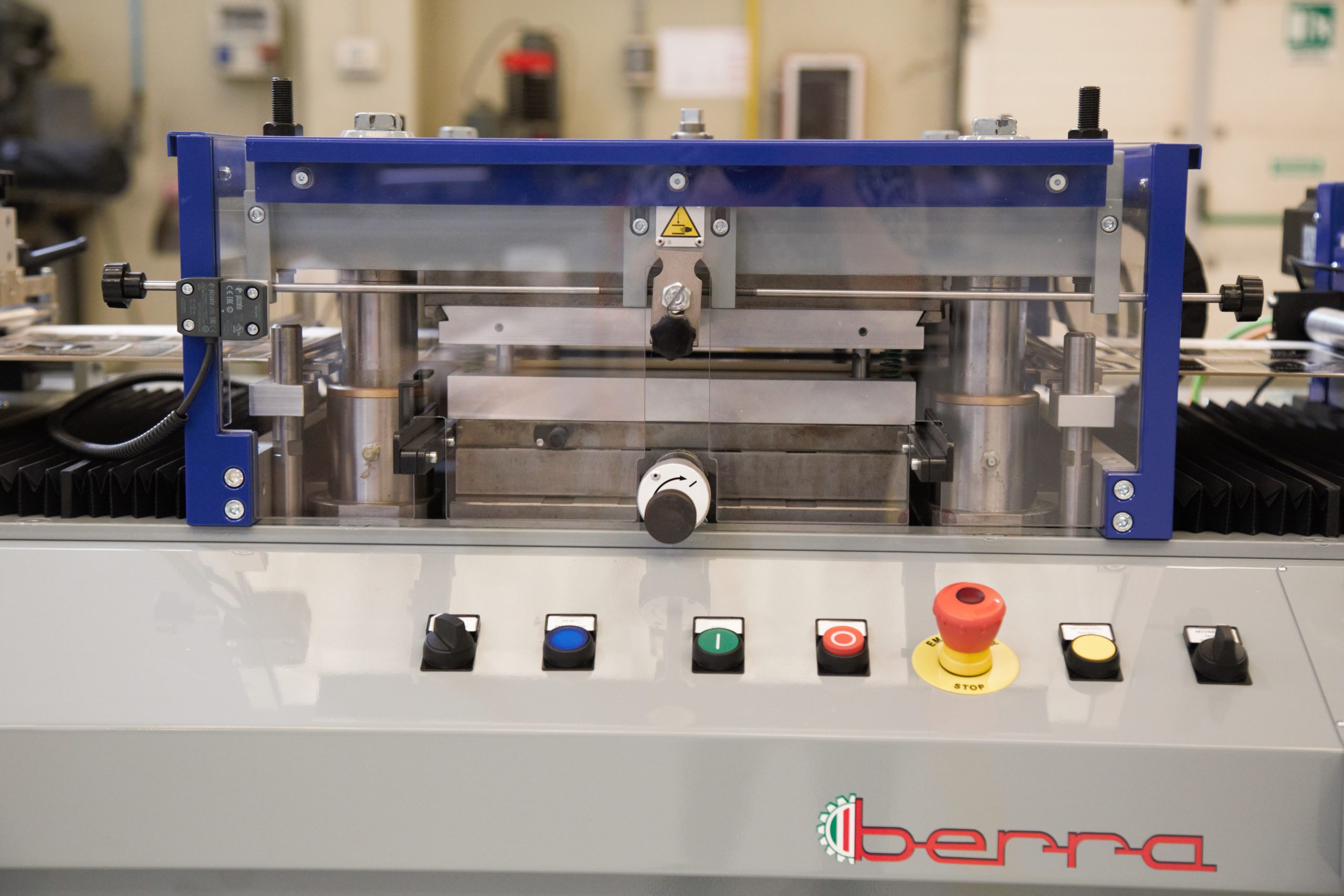

Modular flat die-cutting unit equipped with motorized ball screw for mechanical relief printing and debossing.

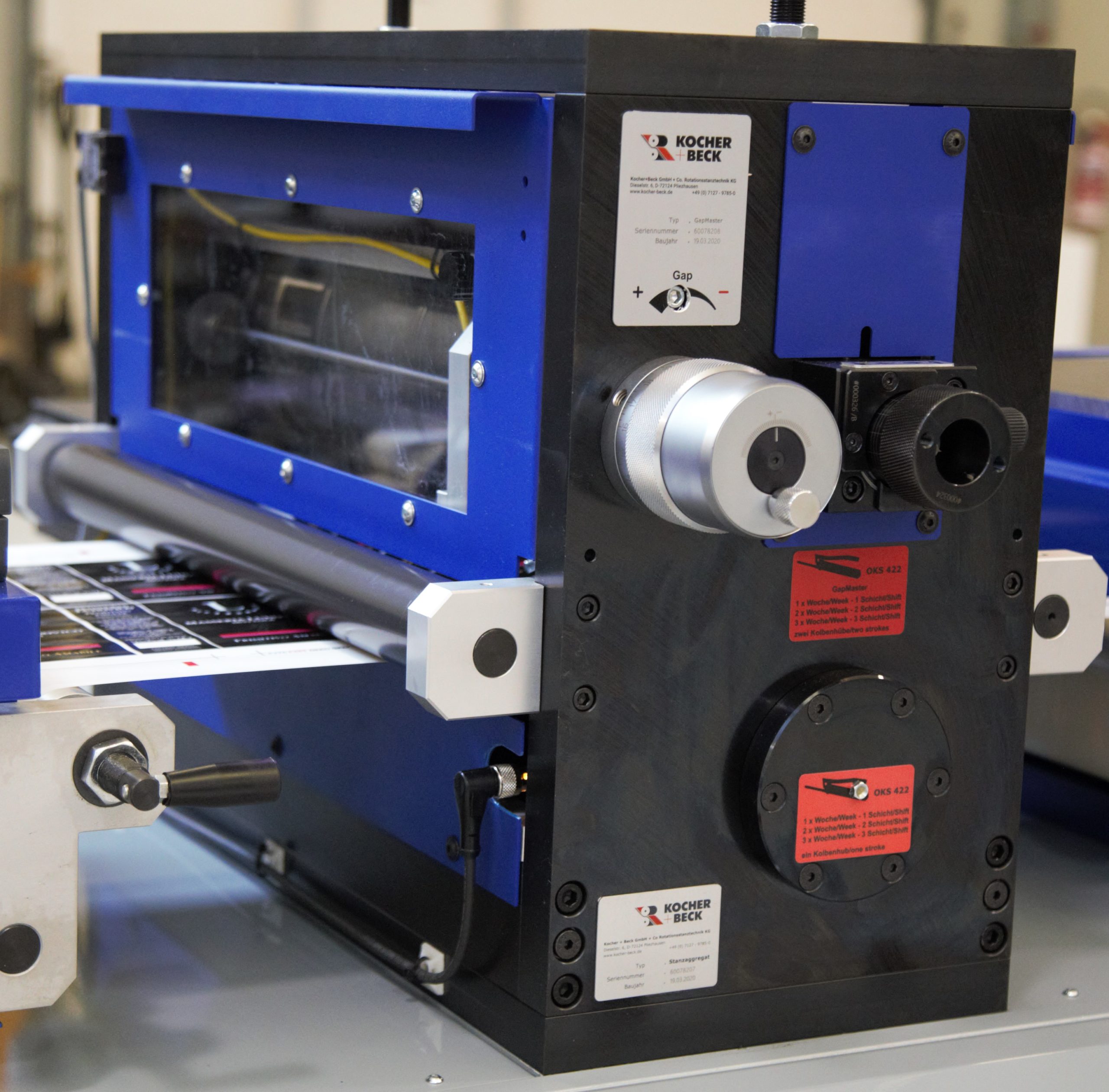

Kocher+beck modular semi-rotary die-cutting unit with latest generation Bosch/Rexroth management software and the possibility of using all “Z” sizes of flexible dies.

The reel is completely finished in the machine.

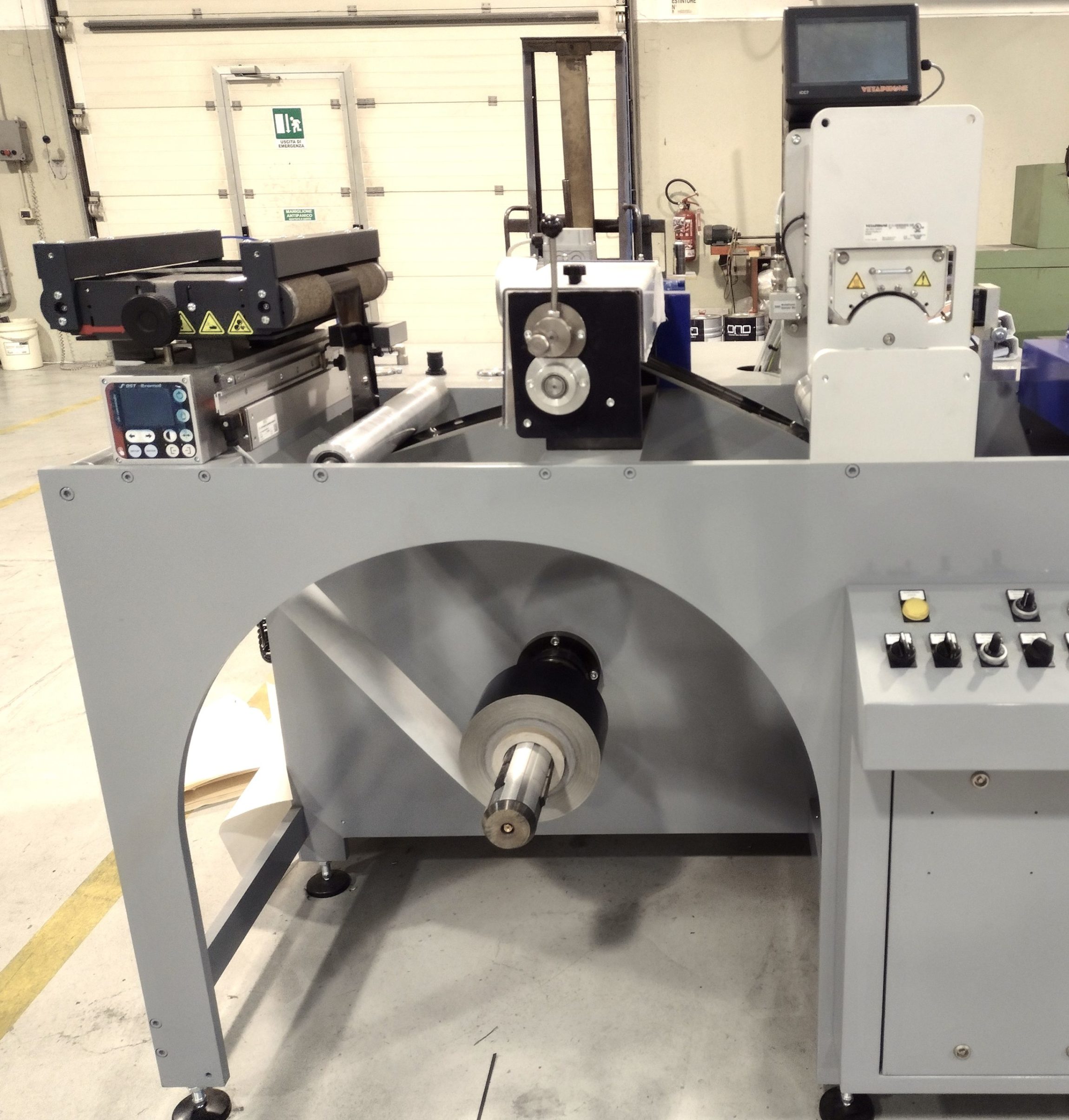

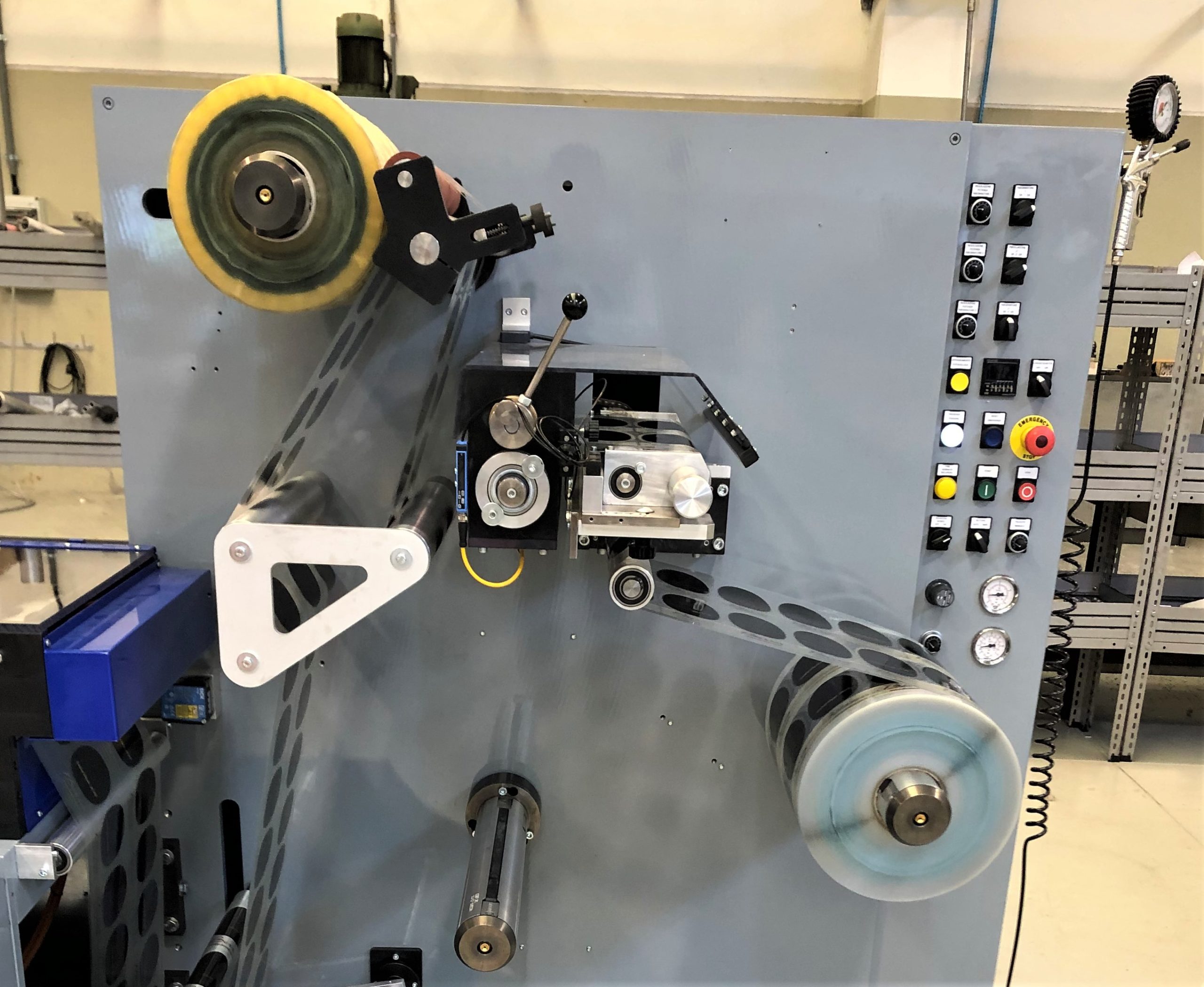

New “Easy Liner New 2025” unwinding/rewinding unit with speed variation.

- Unwinder with BST WebGuide

- Vetaphone Corona Treatment

- Flexo UV and water-based Printing and Varnishing Unit

- Cold Foil and Adhesive and Cold Lamination System

- Diagonal Silk Screen Printing Unit with Autoregister

- Hot Foil Printing Unit with Autoregister and (New 2025m MULTIFOIL) with 90° rotation of the whole Unit

- Enhanced structure, Improved tonnage pressure and heat resistance in the “TOR and EXTRA TOR versions”

- Dry Coating for Label internal parts Removing System

- Flat Die Cutting for embossing and debossing

- Semi-Rotary Die Cutting Unit with GAP MASTER

- EasyLiner waste-Removing/Rewinding Unit (New 2025) with heated plate

| Max. diameter of reels on the unwinder | mm 800 |

Max. diameter of rewound spools | mm 600 |

| Material feeding gap | mm 340 |

Length of single modules |

mm 1.500/2.000 |

| Printing size |

mm 310 x 280 |

Machine depth |

mm 1.500 |

| Remote Service |

Standard |

Flat Screen Printing Unit speed | Up to 5,000 cycles/hour |

| Hot Foil Printing Unit speed | Up to 7,000 cycles/hour |

Flexo Unit and Semi-Rotary Die Cutting speed |

Up to 10,000 cycles/hour |